1 Identifying Problems & Customer Needs

1.1 Identifying the Problem

Albert Einstein is famously credited for stating, “If I had an hour to solve a problem, I’d spend 55 minutes thinking about the problem and 5 minutes thinking about solutions.” While there is little evidence that Einstein was responsible for this remark, the substance of the quote has resounded with scientists and engineers. At the root of the statement is one simple ideology – the most critical and challenging part of the problem-solving method is the definition of the problem.

The idea of meticulously defining the problem is often overlooked by new and inexperienced engineers. Without discipline, the thrill of the design process can overshadow the need for a rigid foundation. Engineering students, trained from the beginning to solve problems as efficiently as fast as possible, easily become fixated on one solution early without really knowing what problem it solves. Failing to correctly identify the problem can result in cost, time, and reputation deficits further down the design pipeline.

Why is it Critical to Define the Problem?

Defining the problem is critical to ensure that the customer and the design engineer agree on the needs that must be addressed by a solution. If the customer and the design engineer do not agree on the problem, it is likely, if not certain, that the design engineer will create a solution to a problem that doesn’t satisfy the customer. To ensure conception of a proper solution, the design engineer is responsible for asking the right questions about the problem both of the customer and other end users.

Consider the following hypothetical: you are a mechanical engineer that aims to develop a chair for a larger company’s headquarters located in Platteville, WI. Upon hearing the need for a chair, you set out to design the best, most capable office chair that has ever existed. The office chair is equipped with lumbar support, armrests, wheels, an ejection seat, and all of the other amenities one could ask for. When you go to present it to the customer, they grow concerned that the chair was intended for use in conference rooms. The inclusion of armrests increases the width of the chairs, which decreases the number of chairs that can fit around a table. Newly inspired, you go back to the drawing board and eliminate the armrests. When you present the result to the customer, they are satisfied with everything except for the cost of the unit. Once again, you return to the drawing board, eliminate the wheels and ejection seat while retaining lumbar support, and present the result to the customer once more. The customer then expresses that they are satisfied with the new cost, but they would have preferred the inclusion of wheels instead of the lumbar support. You grab your office chair, load it up in your vehicle, and head back to your shop to design what will hopefully be your last concept.

Now, consider the case where the size, cost, and other necessary features of the chair were discussed prior to the development of the first model. The problem would have been solved with a greatly reduced number of prototypes. This is the motivation behind defining the problem – to ensure that, in the end, the problem is solved as correctly, efficiently, and elegantly as possible.

The Anatomy of an Engineering Problem

In its purest form, an engineering problem consists of a basic need (pains), a desired outcome (gains), and the context of the problem. The basic need, or customer pains, is best defined by the problem that a customer hopes to address. The basic need is meant to motivate the further progression of the design process, so it should be written clearly and concisely. In the chair example above, the basic need that requires attention is the lack of seating arrangements in the conference rooms.

The desired outcome, or customer gains, is a set of qualitative criteria that the product must fulfill upon its completion (i.e. the goal of the product). It is not meant to act as an exhaustive list of customer needs (which come later), but rather as a high-level description of the functionality of the product. Determining desired outcomes is a preliminary step to listing the customer needs, which require quantitative descriptions. In the chair example, the seating arrangement must be composed of individual pieces (i.e. no benches). More desired outcomes include the ability to easily move the chairs around, the ability to place the chairs around the table, the focus on comfort, and the need to meet a budget.

The contextualization of a problem is meant to increase the awareness of the design team about the customer’s situation. Contextualization includes asking about the company’s previous attempts to manage or solve the problem, the conditions that the company is working in, the suppliers of the company’s existing hardware (in the event of compatibility issues), and other company-specific information. Contextualization notably does not include attempts outside of the company to solve similar problems – this occurs in the research stage of the design pipeline.

If done properly, this process should give the design engineer a good idea about whether or not their firm has the capacity and knowledge base to tackle the project (although the assessment can change in later stages with the introduction of new information).

Are You Solving the Wrong Problem?

The customer’s problem definition often reveals underlying issues about the customer’s interpretation of the problem. In some cases, the customer may be convinced that they require one prescribed solution to solve their problem. If the design engineer determines that another solution is more suitable for the application, it is good practice to discuss the different approaches to ensure that both parties are on the same page. If the design engineer presents a more elegant and more efficient solution to a problem, it could save the customer both time and money.

Consider a case where the customer has a custom lathe that can only hold round stock up to two inches in diameter. The customer wants a lathe that can hold round stock up to three inches in diameter; so they enlist the help of an engineer to design a new lathe. The customer may not be aware that the existing lathe chuck can be swapped for a new custom chuck to accommodate bigger diameter stock. In this case, a lack of feedback from the design engineer could end up costing the customer (and the design engineer) both time and money. In this hypothetical, it is critical that the engineer communicates the alternative solutions to the customer prior to moving to the next stage of the design process.

1.2 Addressing Customer Needs

Customers Aren’t Engineers

Have you ever had a conversation where the person you were talking to used jargon you did not understand? For example, a mechanic trying to explain to a customer how the first cylinder of their engine is running rich due to the fuel injector sensor malfunctioning. Huh? This barrier of communication is something design engineers must overcome. Most customers do not have an engineering degree. Therefore, functions and features they request may be vague or outright impossible. Picture a customer asking for a flying car that runs on renewable energy by next year. It sounds like a great idea to the customer, but the technological limits make it impossible with the current available technology. Thus, the year timeline is improbable.

Engaging with the customers is inevitable to get permission for changes and to present progress on projects. Being able to effectively communicate with the customer is a must. Thus, it is imperative to avoid engineering jargon in these interactions because the customer may not fully comprehend the terminology used to describe the design. Educating them on engineering jargon is a waste of both your time and the customer’s time. Instead, quantify their vague requests by communicating with them in terms they will understand.

1.3 Converting Customer Needs to Quantitative Metrics

After receiving or generating the customer needs statement and verifying that there is not already a viable solution on the market, the customer needs can be mapped to quantitative metrics. Customers tend to use vague, qualitative descriptions to describe their needs. The design engineer must convert the customer needs from qualitative statements of product function into quantitative measures. This step is important because design is driven by customer needs that are often difficult for customers to articulate. For the design to function what the customer envisioned, clearly defined and measurable objectives must be defined early in the design process instead of reliance on common qualitative descriptions such as “I want something that’s easy to use”, “I want something easy to clean”, or “I want something that looks nice”.

The initial design process involves investigating needs from the customer and interacting with the customer to find out what is essential. At the outset, customers might not realize that they want to prioritize something in their design such as weight, size, cost, or functionality. So, it’s important to ask many questions about what they expect from the design. After client/customer interviews, new objectives will likely be added to the customer needs statement, which is a living document that evolves with the design process as all stakeholders learn more about the product or process being created.

In addressing descriptions given by the customer about the product, design engineers must ask questions aimed at finding the how, why, and what of the goal product. The “how” questions address the function of the product, and what process it is aimed to perform. For instance, the engineering design team can ask, “how long will this product be used daily?” The “why” questions must reach an explanation as to the reasoning behind the customer seeking this objective; this may allow the engineers to derive the importance of the customer’s goals. The “what” questions aim to specify features the customer seeks in their goal product. In the conference room chair example given above, one might ask “why is the chair a better alternative over a bench?” The “what” questions can ask, “in what settings will this product be used?” In directing specific questions at the customer, the engineer can begin to categorize the customer’s objectives and define their priority level.

Asking Questions

Conducting an interview with the customer will help them communicate their vision to the design team. In this process, the design engineer(s) must ask the right questions to obtain quantifiable objectives and produce an excellent product for the customer. Customers are not expected to have vast engineering knowledge. Their vision for their desired product normally contains vague descriptions that the engineering team must decipher. For instance, if a customer is interested in realizing a “beautiful” lamp, then the design engineering team must investigate deeper to understand what “beautiful” means for the customer in terms of the product being created. Does it illuminate a certain square footage? Is the light it produces a particular color and brightness? Is the lamp a certain height? Does it accept a specific kind of bulb? All of these “beautiful” lamp elements can be quantified and measured to determine whether customer expectations are met.

1.4 Textbook Problem Analogy to Engineering Design

Engineering coursework involves solving problems after they have already been defined; this situation is almost never the case in real engineering design. The customer and the engineer have different knowledge bases. So, it is important for the design engineer and customer to work synergistically. The consequences of failing to do so parallel the consequences of misinterpreting a textbook problem.

- If customer needs are misinterpreted, the wrong product will be designed. This is analogous to misinterpreting a textbook problem statement and solving for the wrong variable.

- If the desired outcome are not understood, the product may solve basic needs, but it may introduce other problems or complications for the customer. This is analogous to not stating assumptions while solving a problem, not using enough significant figures, or even overcomplicating the problem due to a misunderstanding.

- If the context for the design is not understood, the solution may not work for the particular customer it was designed to please. This is analogous to ignoring the initial values in an initial value problem or the boundary conditions of a differential equation.

1.5 Organizing the Needs via Kano Model Analysis

Role of Kano Model Analysis

In the world of engineering design, understanding and prioritizing customer needs are essential for creating successful products and services. One valuable tool for analyzing and organizing these needs is the Kano Model, which can help guide design engineers in their client-based projects.

The Kano Model, developed by Professor Noriaki Kano in the 1980s, is a theory of product development and customer satisfaction. It provides a framework for understanding and categorizing customer preferences and needs, helping businesses and engineering teams create better products and services. By understanding and applying the model, teams can better identify their value propositions and Hedgehog Concepts, which will be discussed in detail in Chapter 6. The Kano Model can ultimately help create products that stand out in the competitive market.

When customers provide an extended list of needs to be met by the product or service being developed, good organization becomes crucial for an effective design process. Customers have different conscious and subconscious priorities, and to compete successfully, designers must understand these needs better than customers can articulate them. In the context of a capstone project, the insights gained from the Kano Model Analysis prove particularly valuable when identifying the value proposition (Chapter 6) and conducting down-selection to choose the most suitable design for prototyping (Chapter 8).

Categorizing Customer Needs with the Kano Model

The Kano Model classifies product features into three main categories, each with a different impact on customer satisfaction. The model can also be visually represented as a graph, with the two axes indicating the level of functionality and customer satisfaction.

- The horizontal axis (x-axis) represents the level of functionality or the extent to which a product or service feature is implemented. This ranges from “Not Fulfilled” on the left side to “Fully Fulfilled” on the right side.

- The vertical axis (y-axis) represents the level of customer satisfaction, ranging from “Dissatisfied” at the bottom to “Satisfied” at the top.

Three lines on the graph represent the relationship between customer satisfaction and the level of functionality for three main category of needs: performance needs, basic needs, and attractive needs. Understanding the relationship between customer satisfaction and functionality for each category of needs allows designers to concentrate their efforts on the most impactful features and improvements.

a. Performance Needs

These needs, also known as one-dimensional needs, directly influence customer satisfaction depending on how well they are executed and how many are executed. Customers usually articulate these needs in the Customer Need Statement and consciously evaluate them when deciding upon product alternatives. Performance needs often follow the “the more the better” requirement, meaning that the level of customer satisfaction linearly increases as the level of need execution increases.

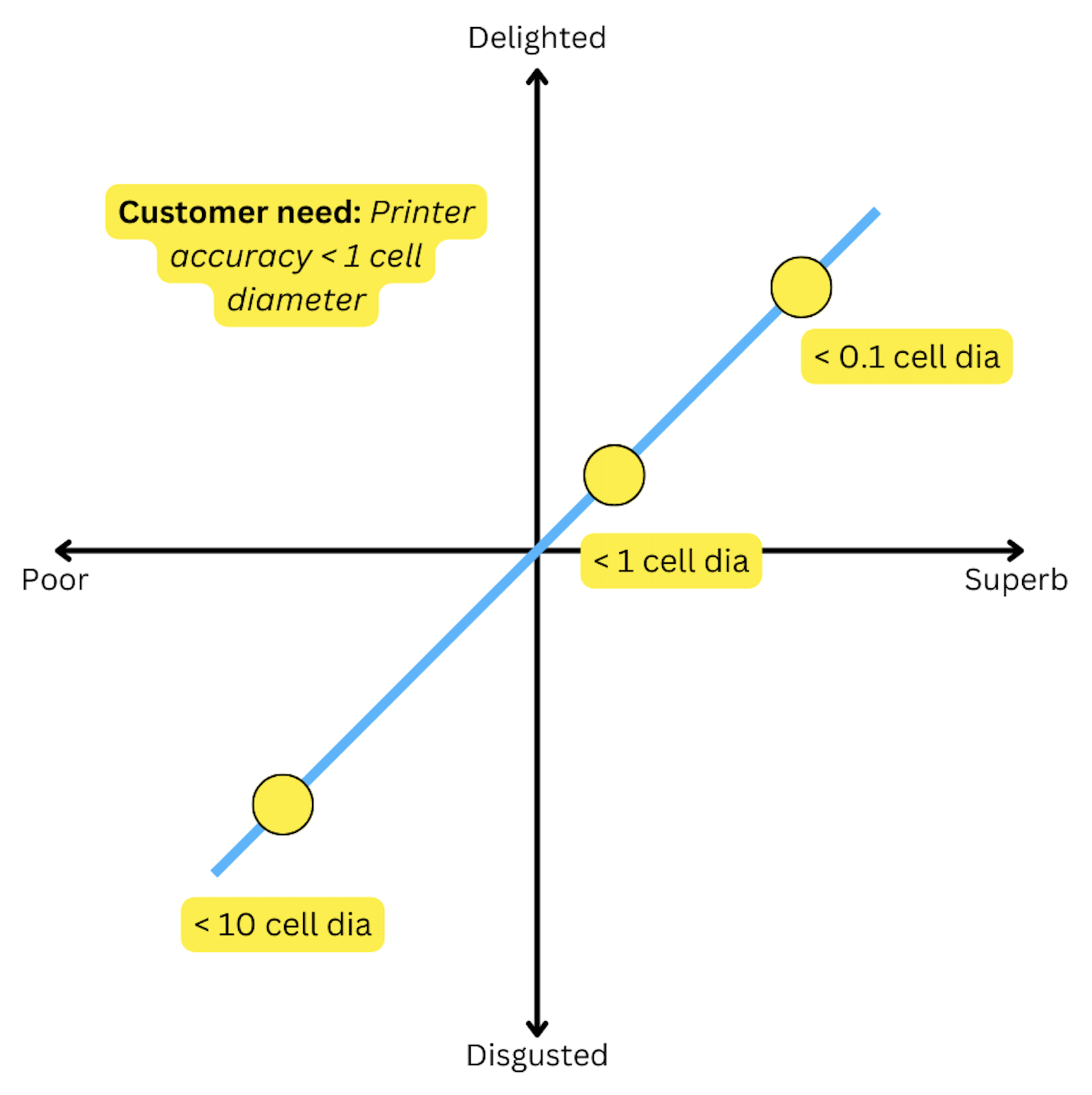

Example 3.1a: 3D Bioprinter Linear Accuracy

You are tasked with designing a 3D bioprinter. Your customer states that the bioprinter must discharge cells with a linear accuracy of less than one cell diameter. This need falls within the performance category of the Kano Model, as it directly influences customer satisfaction based on how well it is executed.

On the Kano Model plot, different levels of accuracy can be represented along the performance line:

- If the bioprinter achieves an accuracy of less than 1 cell diameter, it would be placed somewhere in the middle of the performance line. This level of accuracy meets the customer’s need and would result in a moderate level of satisfaction.

- If the bioprinter achieves an accuracy of less than 0.1 cell diameter, it would be positioned high up on the performance line. This high level of accuracy exceeds the customer’s requirement and would lead to a higher level of satisfaction.

- Conversely, if the bioprinter’s accuracy is less than 10 cell diameters, it would be situated low on the performance line. The printer fails to meet the customer’s need, resulting in a lower level of satisfaction.

b. Basic needs

Basic needs, or must-be needs, are threshold attributes that form the “price” for getting in the door. Customers expect these needs to be met by all products in the category, and they are typically unspoken and not included in the Customer Need Statement unless violated. Even if executed exceptionally well, basic needs do not increase customer satisfaction. However, failing to meet these needs will lead to significant customer dissatisfaction.

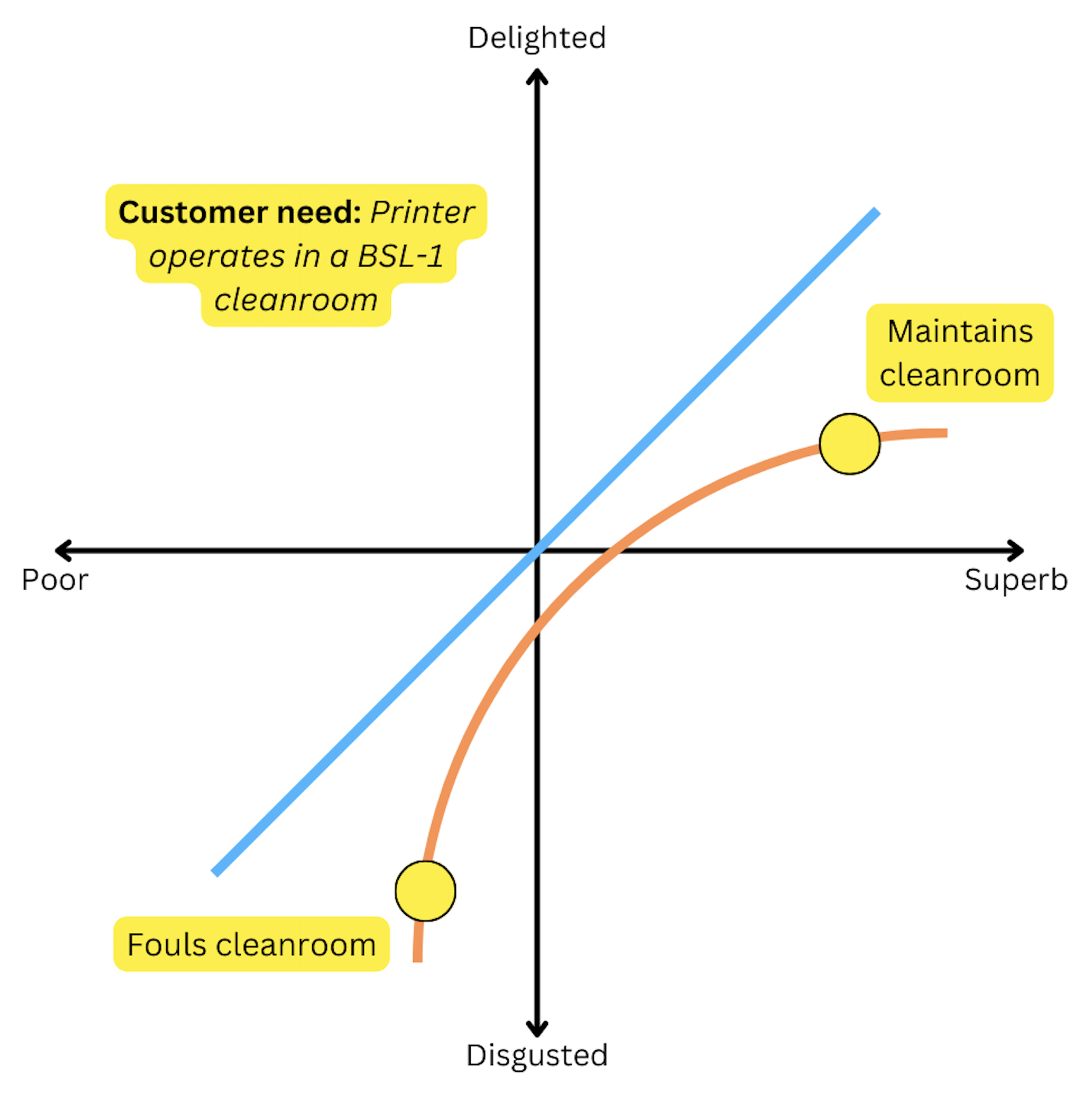

Example 3.1b: BSL-1 Cleanroom

In the context of the 3D bioprinter from Example 3.1a, the customer has mentioned that the bioprinter will operate in a cleanroom with a Biosafety Level (BSL) 1. This need falls within the basic category of the Kano Model, as it represents a threshold requirement that customers expect to be met but will not increase satisfaction if exceeded.

- If the bioprinter successfully operates in and maintains the BSL-1 cleanroom standards, it would be placed high up on the basic line. This means the basic need has been met, and the customers’ dissatisfaction is minimized. However, meeting this requirement would not significantly increase customer satisfaction, as it is a basic expectation that customers take for granted.

- Conversely, if the bioprinter fouls the cleanroom, compromising the BSL-1 standards, it would be positioned low on the basic line. This failure to meet the basic requirement would result in severe customer dissatisfaction.

c. Attractive needs

Attractive needs, or attractive features, are innovations that give products a “wow factor.” They delight customers when delivered but will not dissatisfy customers when missing. Attractive needs are usually unspoken by the customer and absent in the Customer Needs Statement, as customers often don’t know they want them. These needs can anchor a Hedgehog Concept, providing a unique selling point for the product.

Example 3.1c: Number of Cell Types

In the context of a 3D bioprinter, an attractive feature has been identified: the ability to print multiple cell types. By default, the customer expects the bioprinter to be capable of printing only one cell type. Attractive features, as per the Kano Model, have the potential to delight customers when present but do not cause dissatisfaction when absent.

On the Kano Model plot, different levels of cell type printing capabilities can be represented along the attractive line:

- If the bioprinter can print only one cell type, it would be positioned low on the attractive line. As the attractive feature is not present, the customer’s expectations remain unaltered, and their satisfaction level stays neutral.

- If the bioprinter can print several cell types, it would be situated high on the attractive line. In this scenario, the customer would be impressed by the enhanced capability, leading to a significant increase in satisfaction.

This example illustrates the potential impact of attractive features on customer satisfaction. By incorporating the ability to print multiple cell types, designers can differentiate their bioprinter from competitors, providing a unique selling point and exceeding customer expectations.

Attractive Needs “Migrate” Over Time

Over time, customer expectations evolve, and attractive needs can drift to performance needs and eventually become basic needs. This migration highlights the importance of continuous innovation to maintain a competitive edge in the market. As customers become accustomed to certain features, they begin to expect them as standard, underscoring the need for designers to stay ahead of the curve in anticipating and meeting customer desires.

Example 3.1d: Rearview Camera in Automobiles

When rearview cameras were first introduced in cars, they were considered a luxury feature, typically available in high-end models. Drivers appreciated the added convenience and safety that rearview cameras provided, as they made parking and reversing easier and reduced the risk of accidents. At the time, rearview cameras were not a standard feature in all cars, so having one made a vehicle stand out and offered a “wow factor” for drivers.

Over the years, as the technology became more accessible and affordable, rearview cameras started to be included in a wider range of vehicles. Consumer expectations shifted, and the rearview camera transitioned from an attractive need to a basic need. Today, many countries have even made it mandatory for new vehicles to be equipped with rearview cameras. As a result, customers now expect all new cars to have this feature, and a vehicle without a rearview camera would be seen as lacking an essential safety feature, leading to customer dissatisfaction.

Example 3.1e: Wi-Fi Connectivity

When Wi-Fi technology was first introduced in the early 2000s, laptops with built-in Wi-Fi capabilities were considered innovative and provided a “wow factor.” The ability to connect to the internet wirelessly was a significant improvement over relying on Ethernet cables, offering convenience and portability. At that time, not all laptops came with built-in Wi-Fi, making it an attractive feature that differentiated those that did.

As the technology became more widespread and user expectations evolved, Wi-Fi connectivity in laptops transitioned from an attractive need to a basic need. Today, customers expect all laptops to come with built-in Wi-Fi capabilities. A laptop without Wi-Fi connectivity would be viewed as lacking an essential feature, leading to customer dissatisfaction.

Key Takeaways

- An engineering problem consists of a basic need, a desired outcome, and the context of the problem.

- Customers use vague, qualitative descriptions to elucidate their needs. Design engineers must work closely with customers, asking the right questions to obtain quantifiable objectives.

- Customer needs get converted to quantitative metrics, which are both numerical and measurable.

- If the basic need is misinterpreted, the wrong product is produced.

- If the desired outcome is not understood, the product may solve basic needs but introduce other problems or complications.

- If the context is not understood, the solution may not work for the particular customer.