Steel: Carnegie and Creative Destruction

Sean Adams

“Watch the costs and the profits will take care of themselves.” —Andrew Carnegie

Abstract

This chapter uses the rise of Carnegie Steel as a case study to explore the social and economic context of materials innovation. In the United States during the 19th century, steel became a vital element of industrial growth, and Andrew Carnegie revolutionized its production through a system of hard driving at his steel mills outside of Pittsburgh, Pennsylvania. This is an example of the economic theory of creative destruction, in which innovation in technology and the organization of the shop floor replaces long-standing institutions and practices in the production of materials. As a result, there are both gains to society—in this case cheap steel for the construction of things like buildings and railroads, as well as drawbacks for workers and companies that tried to compete with Carnegie. In summary, innovation in the manufacture of materials can be a double-edged sword.

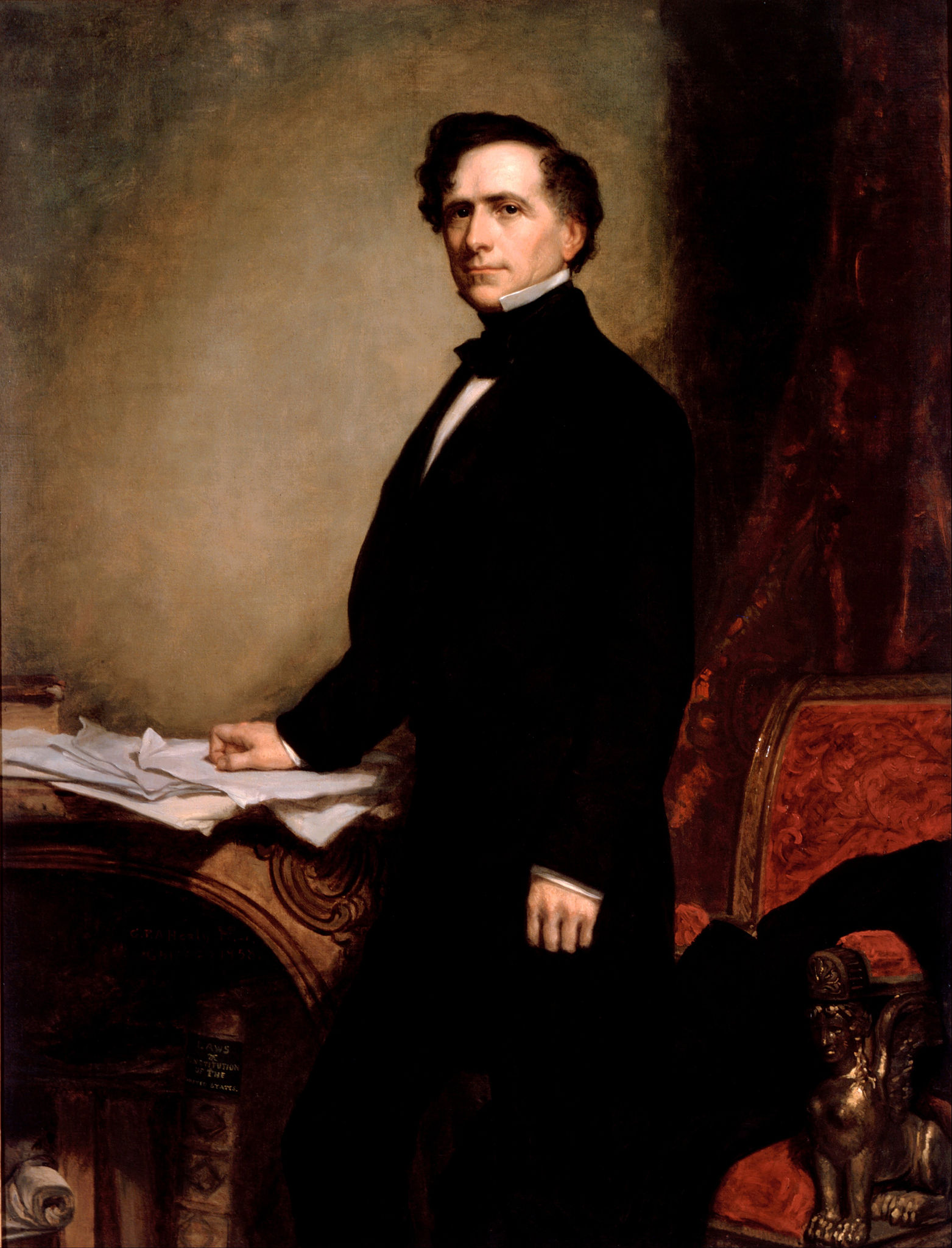

The President and the Weaver’s Son

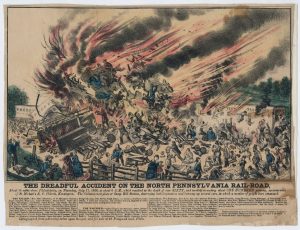

Franklin Pierce should have been celebrating his inauguration as President of the United States in early 1853; instead he was mourning. The New Hampshire Democrat had just won 86 percent of the electoral vote in the presidential election, even though he was a long shot to even win the nomination. Franklin, his wife Jane, and their beloved son Benny boarded a train on January 6, 1853, in Andover, Massachusetts. Less than one mile into the journey, a coupling snapped and the passenger car rolled down an embankment. Jane and Franklin suffered only slight injuries, but Benny was not so lucky. The Pierces watched horrified as the wreckage from the crash decapitated their only living son. Both parents would never be the same again; Jane brooded over the accident and even wrote a letter of apology to her deceased Benny, while Franklin never displayed the political vigor needed to unite a county rapidly coming undone over the issue of slavery.

Although they felt their tragedy intensely, as every grieving parent would, the Pierces’ experience was not a rare occurrence. In only two years, 1850 to 1852, over 900 Americans died in railroad accidents in New York State alone. Deficient parts, such as the coupling that failed the Pierce family in January of 1853, and worn-out iron rails signaled a technological challenge for American railroads, as well as a safety concern that could impact ticket sales.[1]

At the same time that the Pierces mourned Benny, young Andrew Carnegie had his own problems. His father, Will Carnegie, had been a skilled weaver in Scotland. But when a steam-powered loom opened in his hometown of Dumferline, the elder Carnegie struggled to find steady work. “Andra,” he confided to his wife in 1847, “I can get nae mair work.” The next year the Carnegies were on their way to America, where Will still could not find a good job. In 1855, while a gloomy President Franklin Pierce presided over Washington, Will Carnegie died, leaving Andrew to tend to his mother, his younger brother, and fend for himself.[2]

On the surface, the lives of Franklin Pierce and Andrew Carnegie appear very different. What could unite the fourteenth President of the United States and the immigrant son of an underemployed weaver? As it turns out, we can use steel to forge a link between these two stories; in fact, steel tells a great deal of the story of Industrial America. Think of it this way: had Andrew Carnegie’s steel been around in 1853, the history of the Pierce family might be quite different. But even as cheap and durable steel made railroad travel safer during Carnegie’s time, the societal cost—particularly to workers and to Carnegie’s competitors—took an altogether different toll on the US. How this connection between steel and 19th-century Americans took hold is the focus of this chapter. By understanding the context in which steel emerged as an essential material for industrialization, we can appreciate the ways in which new materials enrich our own generation. Steel presents a case study that provides a kind of blueprint for anticipating how the integration of new materials into society can generate both positive and negative results. This case clearly illustrates the impact of materials on society.

Iron and Steel

Iron is the second-most common element on Earth, and humans have worked it into tools, weapons, and other goods for millennia. The process to convert iron ore into metal of various levels of toughness and flexibility is simple and straightforward: cook the impurities (mostly oxygen) away from the ore, leaving the base metal behind. Steel requires a bit more work to make, as it needs a particular amount of carbon—usually between one and two percent by weight—and this kind of precision requires more care than basic iron smelting.

The relationship between humans and iron remained relatively stable over thousands of years until the 19th century, when innovations in production techniques and changes in consumption patterns accelerated the knowledge and practice of iron metallurgy quite suddenly. In fact, these changes occurred so rapidly, we refer to the period as an “industrial revolution,” and iron and steel played an absolutely central role in that phenomenon, particularly in the US. America became connected to steel in so many ways, that by the advent of the 20th century, they didn’t think twice about its presence in their lives.

Why Steel?

In order to understand why steel is so important, we first have to dive into the history of iron. After all, steel is simply an alloy of iron and carbon, but since the common definition of steel is that it contains up to two percent carbon by weight, its history is closely related to iron. The main property that makes iron such a desirable product is its toughness—an iron plow tears through the soil much more effectively than a wood one—but at very high purity levels, iron can be too weak and ductile. Adding carbon to iron adds strength, but maintains the product flexibility; adding too much carbon makes it brittle. Steel with a well-controlled carbon content is the most desirable form of an iron carbon alloy. Steel can maintain a sharp edge quite well, which is why it has been a popular material for making swords for centuries. However, making steel was a difficult, labor-intensive process for most of human history.

Iron, on the other hand, was relatively easy to manufacture. Iron smelting is the manufacturing process that mixes iron ore, a carbon-based fuel like charcoal or coal, and a stabilizing agent such as limestone. Small furnaces were found in ancient China, Mesopotamia, and Rome, which proved that iron smelting has been used for thousands of years. Pure iron reaches a liquid state at temperatures of 1,500 degrees Celsius, which is beyond the capabilities of ancient furnaces. These early furnaces produced a product called a bloom, which is a mixture of pure iron and non metallic oxides. The bloom then had to be heated and hammered in order to remove the oxides. This labor-intensive process meant that iron was a useful material for weapons, small tools, and decorative items, but large-scale manufacturing was not possible.

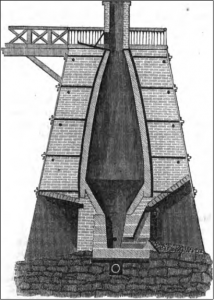

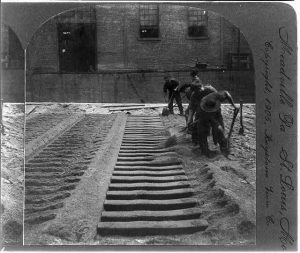

By the 1700s, Europeans were constructing large, tower-like blast furnaces that could run for months on end. These large-scale furnaces could reach temperatures sufficient to create cast iron (iron with >2.3 percent carbon), also known as pig iron, which has a lower melting point than pure iron. The higher temperature of the blast furnaces was achieved by forcing air up through the mixture of iron ore and coke. Coke is coal that was previously heated to reduce the sulfur content. The iron subsequently liquefied at the bottom of the furnace while the impurities in the ore bonded with the limestone or other reactants to form slag, a glassy-like mixture. Once the iron-maker decided the batch was ready, workers tapped the furnace (allowed the molten cast iron to drain off the bottom) and skimmed the impurities or slag off of the top. The molten iron flowed into troughs dug into the sand surrounding the furnace; workers eventually called the cooled iron “pigs” because they looked as if they were baby pigs suckling a large sow. The “pig iron” could then be reworked into iron tools, sash weights, cannonballs, plows, stoves, and other products by pouring, or “casting,” the melted iron pigs into molds, thus the term cast iron. As stated, this form of iron had lots of carbon (>2.3 percent). Once the iron was smelted, blacksmiths could also use finery forges to remove most of the carbon using gas oxidation of the melt, thereby creating wrought iron. Wrought iron could then be worked into steel by adding small amounts of carbon back into the iron, a process called carburization. So, blast furnaces made larger cast iron products more affordable, but cheap steel continued to elude furnace masters.[3]

Iron in the American Context

Early American iron makers built their furnaces in remote locations known commonly as “iron plantations,” because they required close proximity to essential resources such as a moving stream for water power, iron ore, and wood for charcoal fuel. At full capacity a good American blast furnace produced 25 to 30 tons of “pig iron” a week. This raw product made its way to specialized facilities like rolling mills, nailworks, and wireworks that produced more refined types of iron products.

By the early 1700s, British iron makers were forced to use coal in place of charcoal, because of reduced stocks of wood. This technology crossed the Atlantic to appear in American furnaces by the 1840s. The substitution of coal for charcoal reduced the cost of making a ton of pig iron by half. The use of coal also meant that iron furnaces and foundries (those smaller facilities that worked pig iron into useful tools and products) could be built closer to urban centers. As the nation grew, iron became an essential ingredient in American life. Farmers plowed their fields with an iron plow in the morning, cooked their meals in cast iron skillets at midday, stirred their fires with iron tongs to warm the chilly evening air, and then closed their windows at night using iron counterweights.

Iron, Steel and Railroads

At the same time that coal became a common fuel in American furnaces and iron a common product in its households, the nation’s expanding railroad network increased demand for steel. In the three decades before the Civil War, the American railroad network of the United States grew by a factor of ten; these railroads needed iron products such as rails, cars, and other railroad components. American iron producers struggled to meet this demand, and during this period of great expansion, many railroads imported their rails from Great Britain.

Some railroads tried to save on iron by using “strap” rails, which were thin iron strips that sat on top of wooden rails. Iron-starved companies could build a line quickly and cheaply in this fashion, but the strips of iron sometimes came loose and would fly upwards when a passing locomotive ran over them. These “snakehead” rails literally impaled some railroad passengers, and were part of the gruesome reality of early railroad travel. American railroads in the antebellum era (before 1860) also purchased iron products that were of uneven quality. Couplings, axles, and wheels were notorious for failing quickly—and sometimes disastrously—as the Pierce family found out so tragically. Castings made from pig iron were cheap, but the quality was uneven. Without the means of testing it for strength and flexibility, manufacturers made inferior products that often broke down at the most inopportune times.

The Work of Making Steel

Could steel be the solution? Since steel is stronger than cast or wrought iron it became the ideal material for making durable rails and other parts needed to run a railroad safely and efficiently. But at the time when the nation’s rail network needed cheap steel, most of the steel made in the United States at that time was blister steel, which required the repeated application of powdered carbon to superheated wrought iron to add enough carbon to create steel. A skilled blacksmith then repeatedly hammered the carbon into the blade and dunked it into water to quench or cool it rapidly. This ancient art of making high-quality steel was fine for razors and swords; but it was not feasible for the mass production of large industrial products like rails.

Another method of making steel, which also drew upon highly skilled labor, was called puddling. This method of refining involved using the heat of a coal fire to melt pig iron in a furnace while an experienced puddler stirred the molten iron, which burned off impurities while the purer iron formed a pool, or puddled, in the furnace. Eventually the puddler added carbon to the iron and quite literally stirred up a batch of steel. As with blister steel, there was no inherent problem with this method of making steel, other than the amount of time and skilled labor it took. The necessity of skilled labor for this intensive process imbued the workers with a great deal of control. This necessarily raised the cost of production and limited the production output.

In 1856, however, Henry Bessemer invented a process of converting pig iron into steel, which used the injection of a blast of air through molten iron. The Bessemer Process used an egg-shaped furnace that tilted once to accept the molten iron and then returned to an upright position so that impurities could blow out the top of furnace.

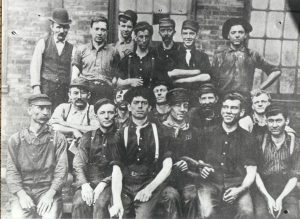

Who Actually Made the Steel?

In the years following the Civil War, most of the power over the steelmaking process resided with the workers. This was reflected in both wages and working conditions. For example, in 1865 the Sons of Vulcan, an organization of iron puddlers, secured a “sliding scale” for their members in which wage rates were tied to the price of iron. However, as new techniques eroded the traditional power and prestige of puddlers and other skilled ironworkers, many employees sought to organize themselves into unions. In 1876, the Sons of Vulcan combined with a number of other trade unions to form the Amalgamated Association of Iron and Steel Workers in Pittsburgh. By 1891, the Amalgamated reached its peak membership of over 24,000 workers organized into 290 local unions. They exerted a great deal of authority and helped organize what had been a fairly diffuse trade.[4]

Who Bought Steel?

These innovations in production were made possible by an insatiable demand for steel in American economy of the late 19th century. After the Civil War, railroads grew at a spectacular rate, until by 1890 they linked the entire continental United States with 167,000 miles of rail; 150,000 miles had been laid since 1865. In 1877 American steelmakers made 432,169 tons of steel rails, considerably more than the 332,540 tons of iron rails produced in the same year.[5] Every American lived and worked, on average, within ten miles of a rail line. This kind of a massive network required a constant influx of cheap steel, as new rail lines went in, old ones were replaced, and rolling stock like locomotives, freight cars, and passenger liners all employed steel parts for their durability and strength. This was no longer Franklin Pierce’s kind of railroad.[6]

As American cities spread out across the country, they also grew up with vertical construction. The massive influx of immigrants to cities across the US made urban areas in the Northeast and Midwest swell in size. During the period from 1860 to 1880, the population of New York City grew from 813,000 to 1.2 million, and Chicago’s population grew from about 112,000 to over 500,000. This kind of rapid growth meant that urban infrastructure was stretched to its limits. In Chicago, a solution came with steel construction. Between 1885 and 1895, Chicago architects developed a close relationship with Pittsburgh steelmakers to develop a “steel-skeleton” design that allowed for individual buildings to double, even triple in height over the traditional brick and mason structures. When William Jenney’s Home Insurance Building was completed in 1884 with structural steel, it was the tallest building in the world at 138 feet.

Fifteen years later, New York’s Park Row Building’s thirty floors stretched 391 feet and helped coin a new phrase: skyscraper. As American cities grew vertically, so did the demand for structural steel.[7]

Railroad construction showed no signs of decreasing, and the application of steel beams to the construction of buildings and bridges meant that iron and steel rails and beams commanded a large share of domestic consumption in the United States. As the industrial economy expanded, the demand for steel in the US seemed insatiable.

The Politics of Steel

Politicians knew that steel was critical to their nation’s success; so American steel enjoyed a protective tariff for most of its rise, which meant that any consumer of imported iron had to pay a sizable duty. To insure this was the case, the American Iron and Steel Association, the industry’s trade organization, teamed up with protectionists in the US Congress like Pennsylvania’s Rep. William “Pig Iron” Kelley. Their efforts ensured that while tariff levels fluctuated in the years prior to 1900, they remained relatively high. Operating with strong tariff protection and utilizing new technologies such as the Bessemer process, the American iron and steel industry blossomed in the years after the Civil War.

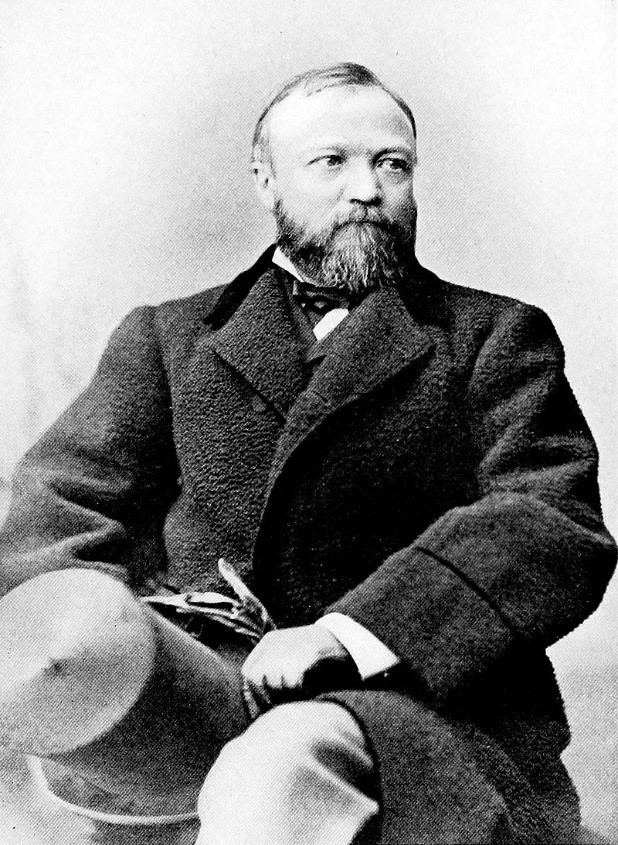

Carnegie and Steel

Here is where Andrew Carnegie reenters the picture, because if you’re going to talk about the rise of cheap steel in the American economy, you need to know the story of Andrew Carnegie. He was not the first person to make steel, nor would he be the last. But his method of doing so would change the course of the industrial economy forever.

By the time Andrew Carnegie immigrated with his family to the United States in 1848, steel was still costly to make, and so his newly adopted country imported a great deal of it from Great Britain. While working as a telegraph operator with the Pennsylvania Railroad, young Andy saw firsthand the American railroad industry’s huge appetite for high-quality steel. After earning a small fortune in the stock market, Andy decided that he wanted to make something rather than just buy or sell things. That something was steel.

Hard Driving

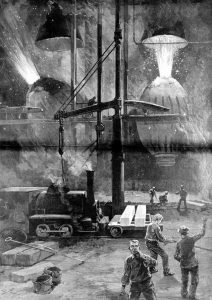

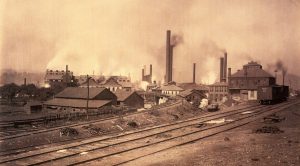

When he finished construction on his Edgar Thomson Steel Works outside of Pittsburgh in 1873, Andrew Carnegie was employing two major business strategies. The first was a tactic called hard driving, in which Carnegie worked his men and his machines to the limit. He used the newly improved Bessemer process for making steel, which required a massive furnace with a specialized lining, which Carnegie’s employees wore out constantly. But he didn’t care, so long as he continued to reduce the cost of steelmaking.

Carnegie Steel hired Alexander Holley to implement Bessemer steel technology, the cutting edge steel making technology at the time, at his mills. When a new and more efficient process known as open hearth was developed, Carnegie simply scrapped the existing equipment and made the transition to the new system. Short-term costs were no object for improved efficiency. For example, once a manager told Carnegie he knew of a rolling-mill design that could roll steel rails more efficiently. Andy ordered the existing rail mill—which was only three months old—ripped out and the new one installed.

Carnegie’s managers tinkered with the process constantly—finding more and more ways to cut the cost of labor and materials. If that meant adopting new techniques, Carnegie’s managers did it quickly; if it meant breaking the power of skilled workers on the shop floor, Carnegie’s managers did it brutally. In the end, hard driving was very successful: the first ton of Carnegie steel cost about $56 a ton to make; by 1900 the cost was down to around $11.50, a dramatic 79 percent cost reduction in about 27 years.

Hard driving is a great example of the more general concept of improving throughput: essentially a measure of the speed and volume that the flow of materials has through a single plant or works. A high rate of throughput—which managers usually measured in terms of units processed per day—became the critical criterion of mass production. It is an important measure of productivity that many businesses sought, to emulate the success of steel.

Key Concept: Bessemer Steel

In 1856, Henry Bessemer introduced, to London’s Royal Academy of Science, a revolutionary process of converting iron into steel, which used the injection of a cold blast of air through molten iron in an egg-shaped furnace—called a “converter”—that transformed iron into steel in a matter of minutes.

Although accounts vary as to who actually “invented” the Bessemer process, we do know that the first working converter in the United States appeared in Troy, New York, in 1864. Soon other firms like the Cambria Iron Works and the Bethlehem Iron Company quickly adapted Bessemer converters to their plants, and Carnegie Steel eventually turned the process into a finely tuned machine.

Carnegie was obsessed with reducing costs via innovation and efficiency, and with his strict adherence to hard driving, his steel factory replaced its Bessemer Converters for the open-hearth process, which is similar to the way steel is made today.

There are only a few Bessemer converters remaining in the US, and most of them are museum pieces.

The Carnegie Legend

By implementing new technology and cost accounting, Carnegie saw one blast furnace increase annual output from 13,000 tons to 100,000 tons. British steelmakers, who had previously dominated the world market in steel rails, couldn’t understand this process and considered it reckless. For example, Carnegie would hard drive a furnace until the lining was completely shot, then he would simply replace his furnaces about once every three years. British furnaces, in contrast, lasted 12 years on average. One British visitor bragged to Carnegie that back home they had equipment they had been using for 20 years. Carnegie reportedly responded, “And that is what is the matter with the British steel trade.” Carnegie streamlined the production process within the plant. Once the blast furnace formed the molten steel into ingots, they were rushed to the rolling mill and made into rails. Another British observer said that he would like to sit on an ingot for a week and watch that mill operate. A manager told him that if he wanted an ingot cool enough to sit on, he’d have to send to Britain for it. When steelmaking changed from the Bessemer system to open-hearth production (a method of steelmaking that relies more on controlling the chemistry), Carnegie removed the Bessemer converters and put in open-hearth furnaces. The end result was that Carnegie consistently slashed prices and undersold competitors.[8]

Vertical Integration

The second major strategy that Carnegie employed was something business historians called vertical integration. Rather than buy the ore, Carnegie bought mining land in Minnesota’s rich Mesabi Iron Range, along with a small fleet of vessels to transport it to Pittsburgh. Rather than buy the best fuel for steelmaking—a refined version of coal called coke (coal with reduced sulfur content)—Carnegie acquired vast coalfields, as well as the beehive ovens that made coke, when he brought Henry Clay Frick, the ruthless coal baron, into Carnegie Steel. By 1900, his company controlled every aspect of steelmaking, from the time the ore left the ground to the time it appeared in the form of a steel rail.

Andrew Carnegie’s many innovations make him a great example of an entrepreneur in America’s Industrial Age. He revolutionized the steel making process, in order to undercut his competitors, increase his share of the steel rail and construction beam markets, and drive any potential competition out of business. As a nation, America benefited from Carnegie’s cheap steel, but there were costs as well.

Creative Destruction

As steel transformed the American landscape in both the city and the country, Andrew Carnegie reshaped both its method and marketing. What would be the impact of these changes? Why are they important?

In 1942, the economist Joseph Schumpeter coined the phrase creative destruction to describe the process of industrial change, particularly in the face of entrepreneurial activity and the incorporation of new technology. Schumpeter was trying to explain how the market economy drives change that benefits society, but at the same time can destroy established ways of doing things. In his book entitled Capitalism, Socialism, and Democracy, he described a process of “industrial mutation” in which a new way of producing goods is “incessantly destroying the old one, incessantly creating a new one. This process of Creative Destruction is the essential fact about capitalism.” [9]

Frick and Homestead

Henry Clay Frick (1849–1919) had built a business empire in the coalfields of Southwestern Pennsylvania. Frick produced the best “coke,” a fuel made by baking coal in beehive-shaped ovens. After consolidating his power in the coking fields of Pennsylvania, Frick joined Carnegie Steel as a partner in 1889.

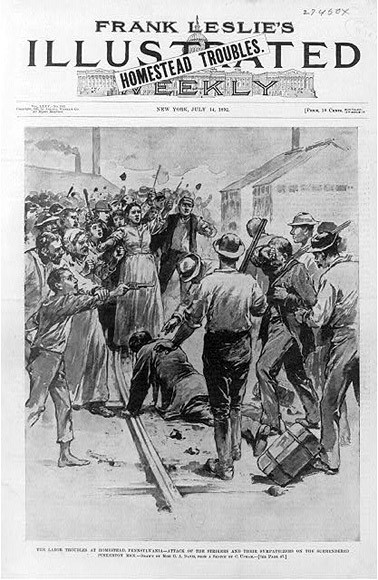

Frick’s iron-fisted tactics in breaking labor unions in his coking operations influenced his approach to the workers’ strike at Carnegie’s Homestead Works in 1892. He locked them out and prepared for a lengthy struggle.

Frick was a loathed figure in the American public eye, but this changed in July of 1892 when an anarchist, Alexander Berkman, tried to assassinate Frick. Berkman burst into his office, shot him twice in the neck and stabbed him four times. Frick survived this attack and returned to work after only a few days. Berkman and his anarchist ties discredited the strike among middle-class Americans, even though the Amalgamated had nothing to do with the assassination attempt.

Carnegie and Competition

Any firms who tried to cut into Carnegie’s market found themselves in a tough spot; Carnegie would drive the price of steel low enough to put the upstarts out of business, only to raise the price back up once the coast was clear. Some immediate benefits of creative destruction were the increased supply of cheap steel rails and structural beams, but in rearranging the way America did business, Andrew Carnegie’s process left wreckage in his wake.

Carnegie Steel’s price leadership limited smaller firms to niche markets such as structural steel, wire, wire nails, rods, and hardware. So it is unfair to say that Andrew Carnegie enjoyed a monopoly on steel production or even an oligopoly. Instead, he drove out competitors in large industrial markets and focused on achieving economies of scale—that is, the reorganization and expansion of the production process so as to reduce costs. In order to succeed with this strategy, Carnegie needed absolute control over the process of making steel, from the raw materials to the finished product.

The Homestead Strike

Because of his working-class background, Andrew Carnegie liked to portray himself as a friend of his workers. In 1889, his workers went on strike at his steel plant in Homestead (outside of Pittsburgh) and Carnegie settled by giving them a contract that set their wages higher than those at neighboring steel mills and negotiated with the union, the Amalgamated Association of Iron and Steel Workers. Homestead was huge—12 mills employing 3,800 men with a town of 11,000 surrounding it.[10]

The integration of new technologies like the Bessemer converter or the open-hearth furnace threatened the Amalgamated’s power. In prior labor conflicts, steelworkers had been able to gain some concessions from their employers like the sliding scale. But when faced with the system of hard driving, the Amalgamated struggled to retain control over the shop floor. This all came to a head in Homestead, Pennsylvania, during a famous strike.

In 1892, when Homestead workers walked off the job, Carnegie left the country to travel to Scotland and left the dirty work of union busting to Henry Clay Frick. Frick announced that Carnegie Steel would only deal with men on a one-to-one basis, and the workers walked out. Frick then set up “Fort Frick,” a 12-foot-high fence topped with barbed wire, and hired 300 Pinkerton Agency detectives as guards. On July 2, he shut Homestead down to lock out the union. When the Pinkerton guards arrived on a barge on the Monongahela River on July 5, the workers met the Pinkertons with gunfire, rock projectiles, and a small cannon. After 12 hours, nine strikers and seven detectives were killed. The National Guard was called out, the Pinkertons were allowed to leave, and Homestead opened with non-union workers. The strike went on until November, when the Amalgamated finally gave up and called it off; the union leaders were fired from Homestead and Frick sent a wire to Carnegie in Scotland: “Our victory is now complete and most gratifying. Do not think we will ever have any serious labor trouble again.” In fact, the steel industry operated without organized labor for the next four decades.[11]

In many ways, the Homestead Strike represented the culmination of years of creative destruction at Carnegie Steel. As a result of hard driving and union busting, Andrew Carnegie had full control over his shop floor. As a result, workers found no choice but to take the wages Carnegie Steel offered and follow the managerial directives that Carnegie Steel wanted. Steelworking would never be the same.

U.S. Steel

In 1900, the financier J.P. Morgan was tired of competing with Carnegie Steel, which kept beating Morgan’s prices in steel-making ventures. So he bought out Carnegie Steel and formed U.S. Steel, the world’s first corporation capitalized at over $1 billion—precisely $1.4 billion. Andrew Carnegie’s personal take in the U.S. Steel deal was over $200 million—billions in today’s dollars—and he was perhaps the world’s wealthiest man. He could not have done it without the creative destruction of the steel industry. Andrew Carnegie’s approach to industrial manufacturing, from hard driving and vertical integration to creative destruction, are all factors that make his story fascinating and important to the rise of steel.

The Legacy

What does this case study in steel tell us about materials? It tells us that innovation can be a double-edged sword, having both positive and negative impacts on societies and the world. On one hand, Carnegie’s cheap and durable steel made railroads more affordable and safer. The story of Franklin Pierce’s tragic loss might have been quite different had Carnegie Steel been available fifty years earlier. On the other hand, Andrew Carnegie’s rearrangement of the shop floor, his ruthless competitive business practices, and his willingness to break the power of labor organizations like the Amalgamated, shattered lives. His own father, Will Carnegie, experienced the destructive side of creative destruction right before moving his family to America. Steel changed the United States by allowing the nation to literally expand both outwards (railroads across the nation) and upwards (skyscrapers) while some Americans, like those workers at Homestead, paid a high price for cheap steel.

Discussion Questions

- Do you think that Andrew Carnegie’s firsthand experience with the mechanization of his father’s workplace might have affected his strategy in steelmaking?

- Do the benefits to society of having an Andrew Carnegie reshaping the steel industry outweigh the costs to workers and competitors?

- Can you think of other examples in which “creative destruction” transformed the production of a material?

- What materials might revolutionize contemporary life if they were suddenly made abundant and cheap?

Key Terms

hard driving

creative destruction

bloom

slag

blast furnace

pig iron

vertical integration

economies of scale

throughput

open-hearth

puddler

Bessemer Process

blister steel

Author Biography

Sean Adams is the Hyatt and Cici Brown Professor of History at the University of Florida in Gainesville, where he teaches courses in the history of American capitalism, the global history of energy and 19th-century U.S. history. His most recent book on energy transitions and home heating is entitled Home Fires: How Americans Kept Warm in the 19th Century (Johns Hopkins, 2014), and it explores the roots of America’s fossil fuel dependency during the Industrial Revolution. He is also the author of Old Dominion, Industrial Commonwealth: Coal, Politics, and Economy in Antebellum America and a three-volume anthology entitled The American Coal Industry, 1789–1902, along with numerous articles, reviews, and book chapters.

Further Reading

Knowles, Anne Kelly. Mastering Iron: The Struggle to Modernize and American Industry, 1800–1868. Chicago: University of Chicago Press, 2013. http://www.worldcat.org/oclc/839276664.

Krass, Peter. Carnegie. Hoboken, NJ: Wiley and Sons, 2002. http://www.worldcat.org/oclc/50143490.

Standiford, Les. Meet You in Hell: Andrew Carnegie, Henry Clay Frick, and the Bitter Partnership That Transformed America. New York: Three Rivers Press, 2005. http://www.worldcat.org/oclc/1150266762.

- Michael Holt, Franklin Pierce (New York: Times Books, 2010), 50, http://www.worldcat.org/oclc/435711537; Mark Aldrich, Death Rode the Rails: American Railroad Accidents and Safety, 1828–1965 (Baltimore: Johns Hopkins Univ. Press, 2006), 19–20, http://www.worldcat.org/oclc/213305539. ↵

- Harold Livesay, Andrew Carnegie and the Rise of Big Business (Boston: Little, Brown and Company, 1975), 7–18, http://www.worldcat.org/oclc/607827467. ↵

- Peter Temin, Iron and Steel in Nineteenth-Century America: An Economic Inquiry (Cambridge, MA: MIT Press, 1964), 57–62, https://archive.org/details/ironsteelinninet00temi.; Robert Gordon, American Iron, 1607–1900 (Baltimore: Johns Hopkins, 2001), 90–124, https://muse.jhu.edu/book/72153. ↵

- David Brody, Steelworkers in America: The Non-Union Era (Cambridge, MA: Harvard Univ. Press, 1960), 50–57, http://www.worldcat.org/oclc/6707478. ↵

- S.H. Finch, “The Iron Industry in its Relation to Railways,” American Railroad Journal 58 (February 1885): 353–54, https://archive.org/details/5088829_58. ↵

- Walter Licht, Industrializing America: The Nineteenth Century (Baltimore: Johns Hopkins Univ. Press, 1995), 82–83, http://www.worldcat.org/oclc/655201338 ↵

- Thomas Misa, A Nation of Steel: The Making of Modern America, 1865–1925 (Baltimore: Johns Hopkins Univ. Press, 1999), 45–89, http://www.worldcat.org/oclc/540692649. ↵

- Harold Livesay, Andrew Carnegie, 109–23. ↵

- Joseph Schumpeter, Capitalism, Socialism, and Democracy (New York: Harper and Brothers, 1942), 83, http://www.worldcat.org/oclc/30488029. ↵

- Paul Krause, The Battle for Homestead: 1880–1892 (Pittsburgh: Univ. of Pittsburgh Press, 1992), 245–51, http://www.worldcat.org/oclc/608933009. ↵

- David Nasaw, Andrew Carnegie (New York: Penguin, 2006), 428–38, http://www.worldcat.org/oclc/255688279. ↵

Feedback/Errata